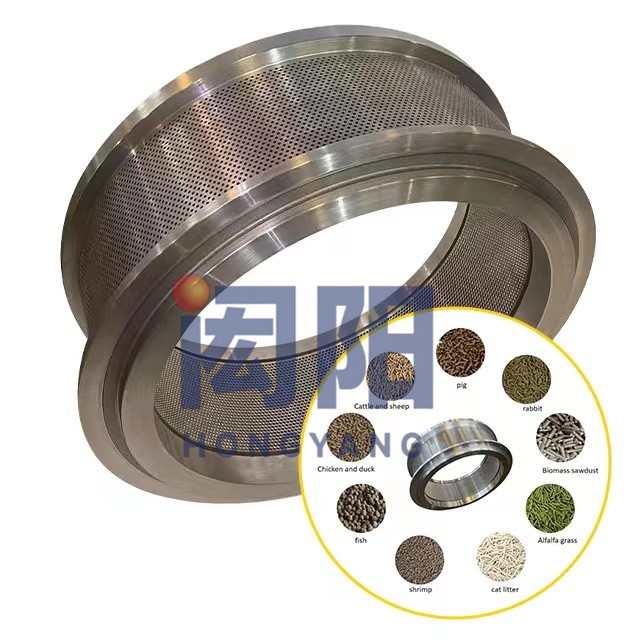

Mutuwar zobe wani muhimmin bangare ne na injin granulator/pellet, kuma aikinsa ya fi kayyade yadda ake sarrafa abinci, yana taka muhimmiyar rawa a cikin tsarin sarrafa abinci. Koyaya, wasu abokan ciniki sun ba da rahoton cewa yayin aikin samarwa, zobe na iya fashe.

An taƙaita dalilai masu zuwa ta hanyar gwaji:

1. Ayyukan kayan aiki da aka yi amfani da su a cikin zobe ya mutu ba shi da kwanciyar hankali da rashin daidaituwa;

2. Idan adadin buɗewar zoben ya mutu ya yi yawa, ƙarfi da taurin zoben ya mutu da kansa zai ragu;

3. Kaurin zobe ya mutu yana da bakin ciki sosai, kuma ƙarfin zoben ya mutu yana raguwa;

4. An kashe zobe da ƙarfi da ƙarfi da abubuwa masu wuya yayin aiki;

5. Yanayin eccentric ko rashin daidaituwa na ƙarar zobe ya mutu yayin shigarwa (maida hankali tare da taron abin nadi, da dai sauransu) yana sa zobe ya mutu don ci gaba da jure wa tasirin unidirectional.

Mold / zobe mai kauri ya mutu don haɓaka ingancin barbashi, saboda ƙarar pellets abinci da gogayya tsakanin bangon mutu, kuma ya ɗaga ƙimar sitaci gelatinization. Koyaya, yin amfani da ƙura mai kauri ko buɗaɗɗen bakin ciki na iya rage yawan aiki. Bugu da kari, nisa tsakanin rollers da mold ya karu daga 0.1 mm zuwa 2 mm, zai iya inganta karko na barbashi.

A matsayin abokin ciniki na mu Hongyang Feed Machinery Company, mu samar da abokan ciniki da mafi girma ingancin zobe mutu, mafi m, kuma yana da mafi girma samar iya aiki. Muna ba da shawara da keɓance mafi dacewa da matsi rabo da buɗe ido ga abokan ciniki.

Bayanin Tuntuɓar Tallafin Fasaha:

TEL/Whatsapp: +86 18912316448

E-mail:hongyangringdie@outlook.com

Lokacin aikawa: Satumba 11-2023