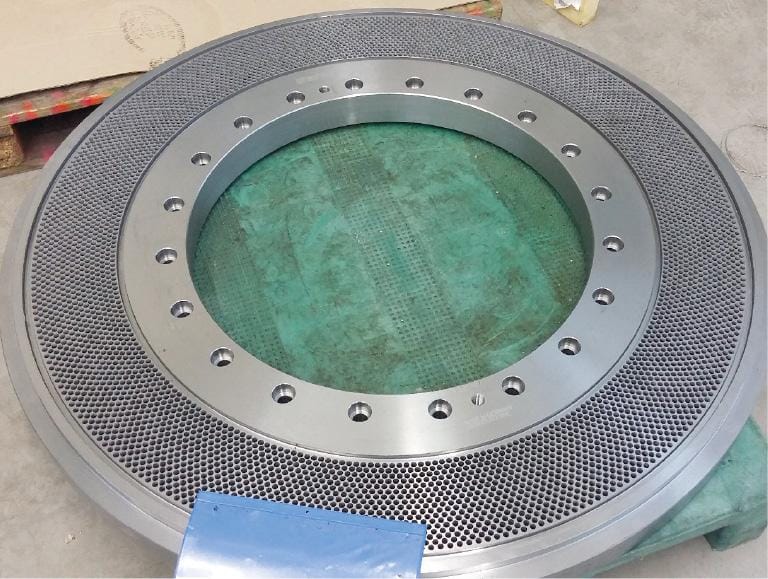

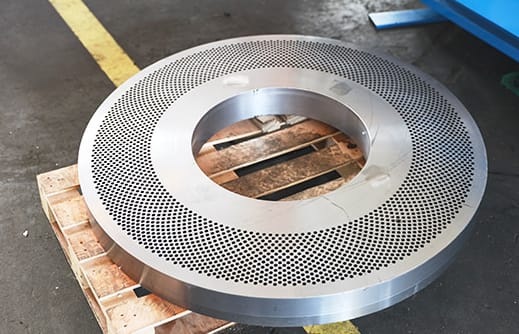

Pellet Mill Flat Die

Siffofin Samfur

Don injin pellet na KAHL (Flat die): KAHL38-780, KAHL37-850, KAHL45-1250, da sauransu.

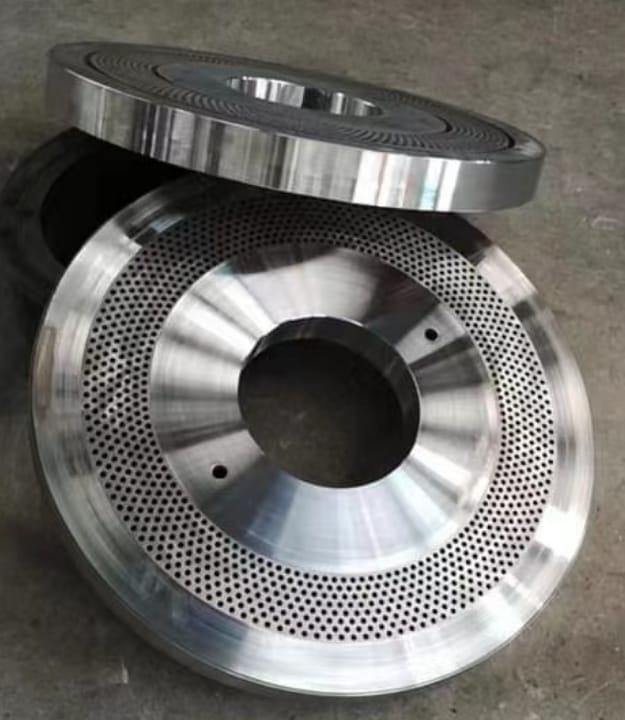

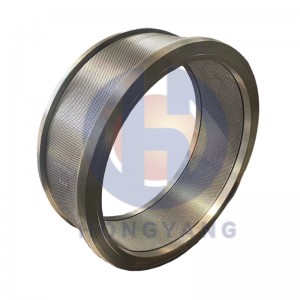

1. Material na zobe mutu: X46Cr13 / 4Cr13 (bakin karfe), 20MnCr5 / 20CrMnTi (alloy karfe) ko musamman

2. Ring mutu taurin: HRC54-60.

3. Diamita na mutuwar zobe na iya zama: 1.0 mm har zuwa 28 mm

4. Nau'in mutuƙar barbashi na iya zama: mold na annular ko mutuƙar lebur

5. Diamita na waje na iya zama kamar 1800 mm

Bayanin samfur

Tushen injin pellet yana ɗaya daga cikin mahimman sassan injin pellet. Faifai ne mai ramuka a cikinsa wanda ake tilastawa albarkatun ƙasa ta cikin matsanancin matsin lamba don samar da pellets. Ramukan da ke cikin ɗakin kwana suna ƙayyade girman da siffar pellets. Anan akwai wasu mahimman bayanai game da injin niƙa pellet.

1. Mutuwar injin pellet ɗin da aka yi shi da kayan da ba su da ƙarfi kamar ƙarfe ko ƙarfe mai ƙarfi saboda yana sarrafa kayan ƙura a ƙarƙashin matsin lamba.

2. Mutuwar lebur tana da ramuka da yawa na takamaiman diamita. Yayin da injin injin pellet ke tura kayan ta cikin ramukan mutu, ana siffanta su zuwa nau'i mai girman girman da ake so.

3. Ƙimar mutuwa mai lebur da adadin ramuka na iya bambanta dangane da girman injin pellet da iya aiki. Manya-manyan injunan pellet na iya samun fashe fashe da yawa suna aiki tare.

4. Mutuwar lebur tana jujjuyawa cikin babban sauri kuma tana aiki tare da taron nadi wanda ke damfara kayan ta cikin ramukan mutu.

5. Mutuwar lebur tana buƙatar kulawa da maye gurbin lokaci-lokaci saboda lalacewa daga matsanancin matsin lamba da abrasion. Ƙananan ramuka a cikin mutu yana taimakawa wajen yanke kayan da kuma samar da pellets masu kyau.