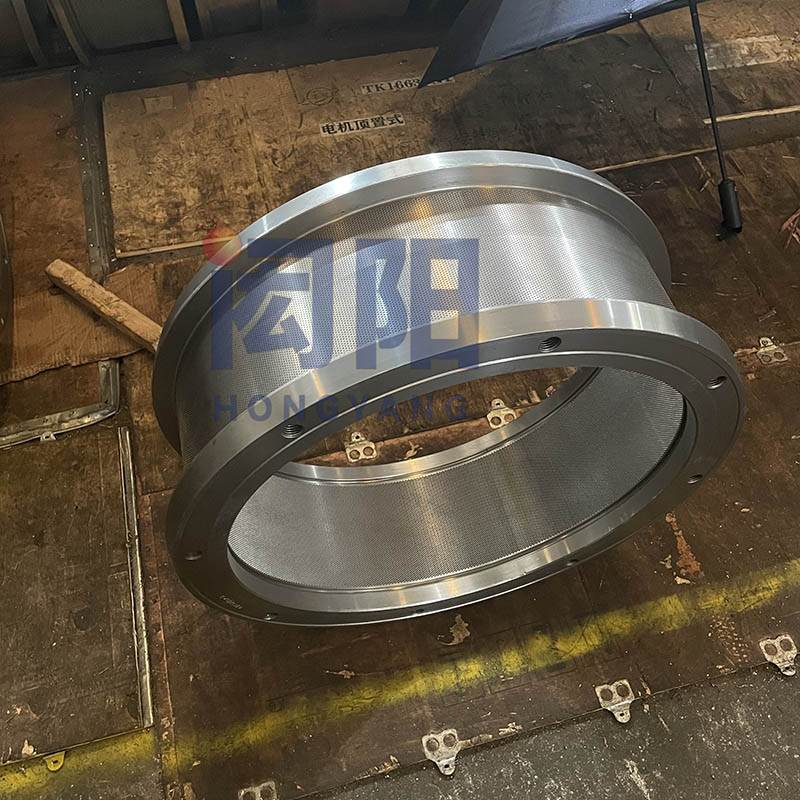

IDAH Ring Die Pellet Machine Parts

IDAH Ring Die

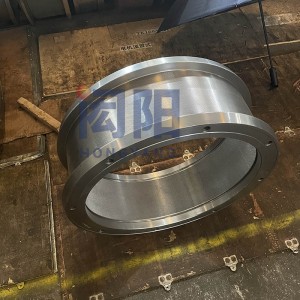

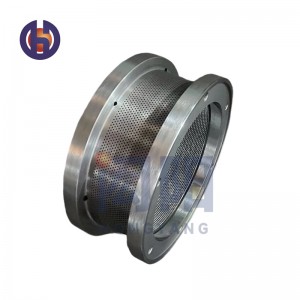

1. Zaɓi kayan albarkatun ƙasa masu inganci, ƙera ƙarfe na biyu, da ɓangarorin ƙarfe na ƙarfe;

2. Ring mutu abu: X46Cr13 (bakin karfe)

3. Multihead shigo da bindiga rawar soja, daya-lokaci gyare-gyaren, high quality, low rami plugging kudi, da kuma high fitarwa kudi;

4. Haɗin wutar lantarki da wutar lantarki mai ci gaba da haɓaka rayuwar sabis;

5. Keɓance rabon matsawa da ƙarfi bisa ga albarkatun abokin ciniki da buƙatun;

6. Ƙaddamar da gudanar da bincike mai inganci yayin duk aikin samarwa don tabbatar da ingancin samfurin.

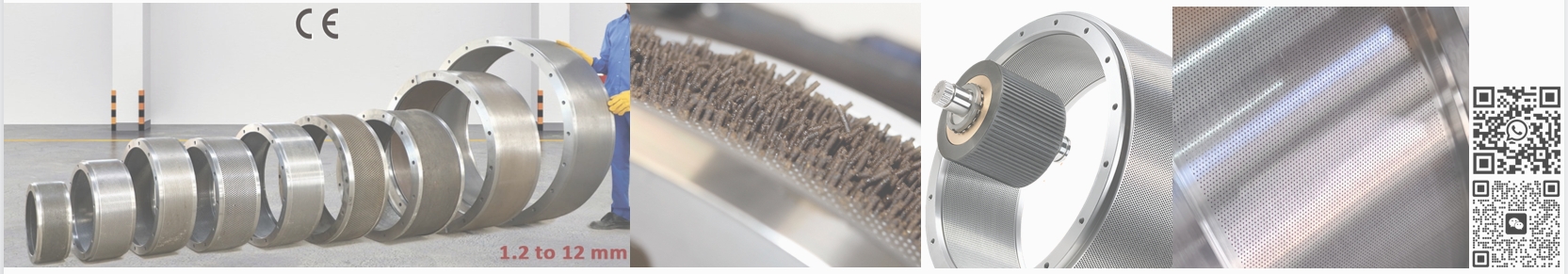

| S/N | Samfura | SizeOD * ID * faɗin faɗin * faɗin kushin -mm | Girman rami mm |

| 1 | IDAH530 | 680*530*258*172 | 1-12 |

| 2 | IDAH530F | 680*530*278*172 | 1-12 |

| 3 | IDAH635D | 790*635*294*194 | 1-12 |

Rabon Matsi

Menene rabon matsi na zobe mutu?

Matsakaicin matsawa na mutuwar zobe shine rabo na ingantaccen tsayin aiki na ramin mutuwar zobe da diamita na ramin mutu.Fihirisa ce mai nuna ƙarfin extrusion na abincin pellet.Mafi girma da matsawa rabo ne, da karfi da extruded pellets ne, amma fitarwa zai zama in mun gwada da m.Karami da matsawa rabo, da rougher saman pellet zai zama da kuma mummunan forming zai zama, amma fitarwa zai zama babba.

Yadda za a zabi daidai rabo rabo?

Saboda daban-daban formulations, albarkatun kasa, da granulation tafiyar matakai, zabar wani dace matsawa rabo dogara a kan halin da ake ciki.Mai zuwa shine kewayon gabaɗaya bisa ƙwarewa:

Ciyarwar dabbobi da kaji: 1:8 zuwa 13;Ciyarwar Kifi: 1:11 zuwa 16;

Ciyarwar shrimp: 1:16 zuwa 25;Ciyar da zafin jiki: 1: 7 zuwa 9;Abincin abinci da bambaro: 1: 5 zuwa 7.

Bayan yin amfani da mutuwar zobe, mai samar da abinci kuma zai iya daidaita buɗaɗɗen buɗaɗɗen buɗaɗɗiya da matsi na zobe na gaba ya mutu daidai da yanayin waje na ciyarwar.

Fasahar Gudanarwa

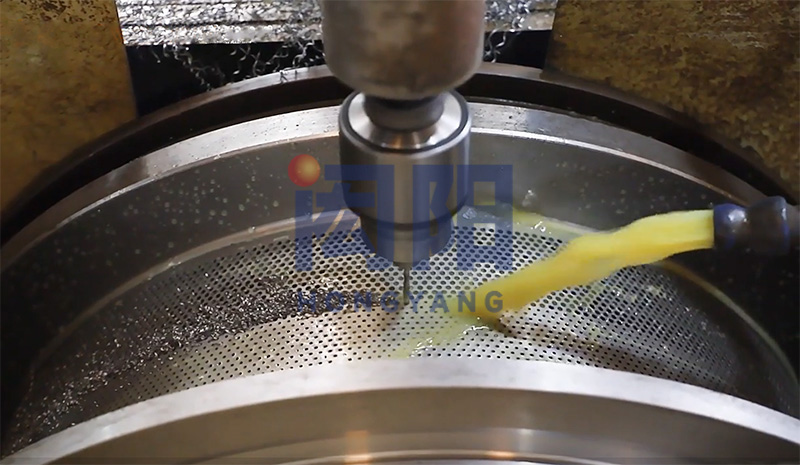

Fasahar sarrafa zobe: Yanke → Kirkira → Roughing → Normalizing → Gama → Quenching and tempering → Gama → Ramin hakowa → Nitriding → Polishing → Gwajin matsin lamba → Juriya → Rusty oil → Dubawa da adana zaɓuɓɓuka