A lokacin aikin granulation na injin pellet ɗin abinci, akwai nau'ikan nau'ikan abinci guda ɗaya ko nau'ikan abinci guda ɗaya masu launuka daban-daban, waɗanda akafi sani da "Flower Feed".Wannan halin da ake ciki shi ne na kowa a cikin samar da ruwa abinci, yafi bayyana a matsayin launi na mutum barbashi extruded daga zobe mutu zama duhu ko haske fiye da sauran al'ada barbashi, ko surface launi na mutum barbashi zama m, game da shi rinjayar bayyanar ingancin na dukan tsari na ciyarwa.

Manyan dalilan da suka haifar da wannan al'amari sune kamar haka.

a)Abun da ke tattare da albarkatun abinci yana da wahala sosai, tare da nau'ikan albarkatun kasa da yawa, gauraya mara daidaituwa, da rashin daidaituwar abun ciki na foda kafin sarrafa barbashi na abinci.

b)Abubuwan da ke cikin danshi na kayan da ake amfani da su don granulation bai dace ba.A cikin tsarin samar da abinci na ruwa, sau da yawa ya zama dole a ƙara ɗan ƙaramin ruwa zuwa mahaɗin don rama asarar ruwa a cikin albarkatun ƙasa bayan murkushe ultrafine.Bayan hadawa, sai a aika zuwa kwandishan don yin zafi.Wasu masana'antun ciyarwa suna amfani da tsari mai sauƙi mai sauƙi don yin ciyarwa - sanya kayan da ake buƙata don tsarin kai tsaye a cikin mahaɗin kuma ƙara isasshen ruwa, maimakon aiwatar da tsari daki-daki da jinkirin ƙara tsari bisa ga buƙatun ƙwararru.Sabili da haka, suna da wuya a tabbatar da daidaiton rarraba kayan abinci na abinci dangane da narkewar ruwa.Lokacin da muka yi amfani da waɗannan abubuwan da aka haɗe don maganin kwantar da hankali, za mu ga cewa saboda ingancin na'urar kwandishan, abun ciki na danshi ba zai iya bazuwa da sauri daidai ba.Sabili da haka, balaga na samfuran abinci da aka sarrafa a ƙarƙashin aikin tururi ya bambanta sosai a tsakanin sassa daban-daban, kuma matsayi na launi bayan granulation bai isa ba.

c)Akwai kayan da aka sake yin fa'ida tare da maimaita granulation a cikin kwandon granulation.Za'a iya canza kayan granular bayan granulation kawai zuwa samfurin da aka gama bayan an sanyaya da kuma dubawa.Fitar foda mai kyau ko ƙaramin abu sau da yawa yana shiga tsarin samarwa don sake granulation, yawanci a cikin mahaɗa ko jiran granulation silo.Saboda gaskiyar cewa irin wannan nau'in kayan dawowar an sake sabunta shi da granulated, idan an haɗe shi ba daidai ba tare da sauran kayan taimako ko haɗe shi da na'ura mai ƙananan kayan aiki bayan an daidaita shi, wani lokaci yana iya samar da "kayan fure" don wasu tsarin abinci.

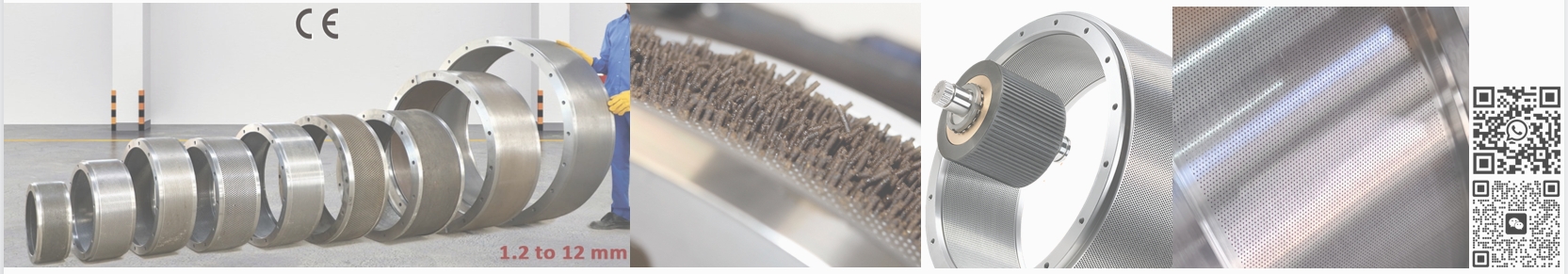

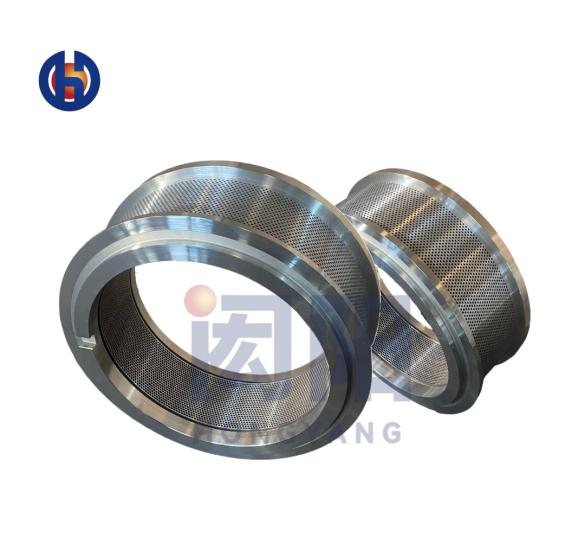

d)Santsi na bangon ciki na zobe mutu budewar bai dace ba.Saboda rashin daidaituwa na ƙarshen ramin mutuwa, juriya da matsa lamba da abin da abin ke fuskanta yayin extrusion ya bambanta, yana haifar da canje-canjen launi marasa daidaituwa.Bugu da ƙari, wasu zobe sun mutu suna da burrs a kan ƙananan ganuwar ramin, wanda zai iya tayar da farfajiya na barbashi a lokacin extrusion, wanda ya haifar da launi daban-daban na nau'i-nau'i.

Hanyoyin ingantawa don dalilai guda huɗu na samar da "kayan furanni" da aka jera a sama sun riga sun fito fili sosai, galibi suna sarrafa daidaituwar haɗaɗɗen kowane bangare a cikin dabarar da kuma haɗuwa da daidaituwar ruwan da aka ƙara;Inganta quenching da tempering yi na iya rage canza launi;Sarrafa kayan injin dawowa.Don dabarun da ke da alaƙa don samar da "kayan fure", yi ƙoƙarin kada ku ɓata kayan injin dawo kai tsaye.Ya kamata a haxa kayan injin da aka dawo da shi tare da albarkatun ƙasa kuma a sake murkushe su;Yi amfani da zobe mai inganci don sarrafa santsin ramukan mutu, kuma idan ya cancanta, niƙa zoben mutun kafin amfani.

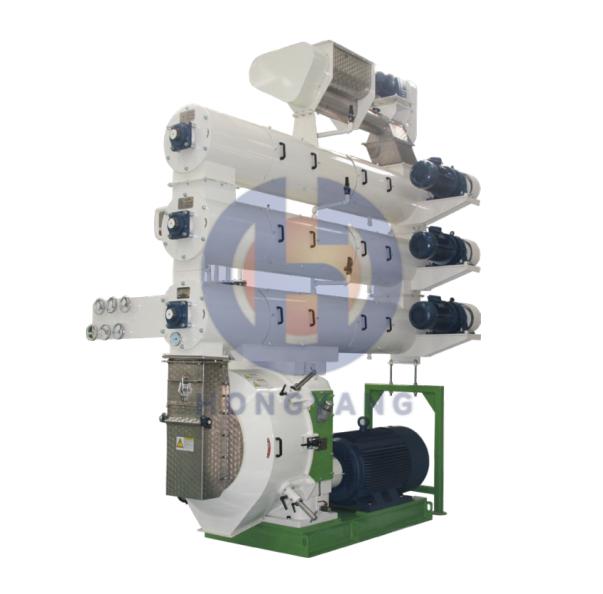

Ana ba da shawarar saita kwandishana mai ban sha'awa mai nau'i biyu-Layer dual axis da na'urar kwandishana mai tsayi biyu, tare da lokacin kashewa har zuwa 60-120 seconds da zafin jiki na sama da 100 ℃.A quenching ne uniform kuma aikin yana da kyau.Yin amfani da iskar iska mai yawa yana ƙara haɓaka yanki na yanki na kayan abu da tururi, don haka inganta balaga na kayan aiki da haɓaka tasirin quenching da tempering;Na'urar kayan aiki na dijital da firikwensin zafin jiki na iya nuna yanayin zafin jiki, yana sauƙaƙa wa masu amfani don sarrafawa a kowane lokaci.

Bayanin Tuntuɓar Tallafin Fasaha:

WhatsApp : +8618912316448

Imel:hongyangringdie@outlook.com

Lokacin aikawa: Yuli-26-2023