A cikin ainihin samar da abinci, saboda dalilai daban-daban, ana iya samar da "tukunyar kayan aiki" tsakanin zobe mutu da abin nadi na matsin lamba, wanda ke haifar da matsaloli irin su cunkoso, toshewa, da zamewar granulator.

Mun zana ƙarshe mai zuwa ta hanyar bincike mai amfani da gogewar wurin harka:

Mun zana ƙarshe mai zuwa ta hanyar bincike mai amfani da gogewar wurin harka:

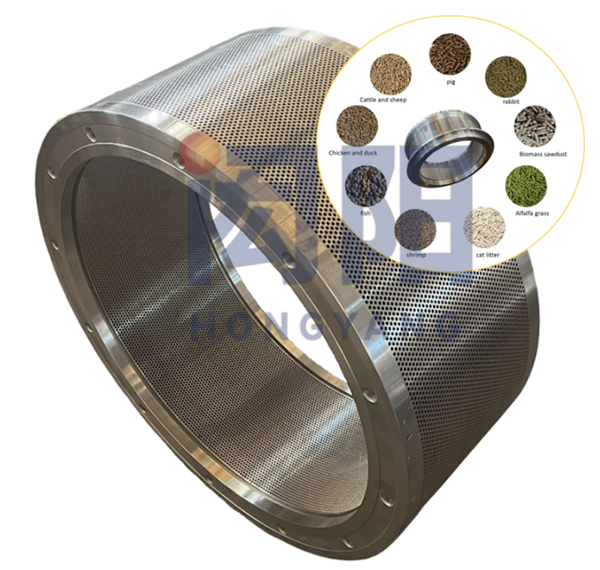

1. Abubuwan da ake amfani da su

Abubuwan da ke da babban abun ciki na sitaci suna da haɗari ga gelatinization na tururi kuma suna da wani danko, wanda ya dace da gyare-gyare; Don kayan da ke da ƙananan zaruruwa, ana buƙatar ƙara yawan adadin man shafawa don rage juzu'i yayin aikin granulation, wanda ke da fa'ida ga kayan don wucewa ta ƙirar zobe kuma abin da ya haifar da granular yana da bayyanar santsi.

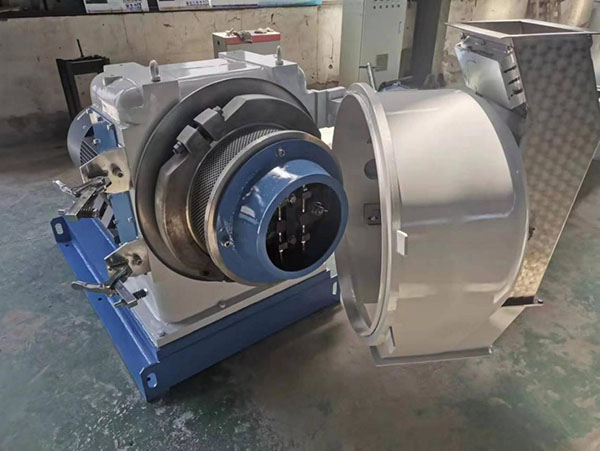

2. Ba daidai ba mutun nadi

Tazarar da ke tsakanin ƙwanƙolin ƙirƙira ya yi girma da yawa, yana haifar da abin da ke tsakanin kayan na'ura ya zama mai kauri sosai kuma ba a rarraba ba. Nadi na matsa lamba yana da wuyar zamewa saboda rashin daidaituwar ƙarfi, kuma kayan ba za a iya matse shi ba, yana haifar da toshewar injin. Don rage toshewar na'ura, ya kamata a biya hankali ga daidaita rata tsakanin masu yin na'ura yayin samarwa, yawanci 3-5mm an fi son.

Yanayin da ya dace don tsarin granulation shine: abun ciki mai dacewa da danshi na albarkatun kasa, kyakkyawan ingancin tururi, da isasshen lokacin zafi. Don tabbatar da ingancin barbashi mai kyau da babban fitarwa, ban da aiki na yau da kullun na sassa daban-daban na granulator, ingancin busassun busassun busassun tururi ya kamata a tabbatar da su cikin kwandishan na granulator.

Rashin ingancin tururi yana haifar da babban danshi na kayan yayin fita daga kwandishan, wanda zai iya haifar da toshewar rami mai sauƙi da zamewar abin nadi a lokacin aikin granulation, wanda ke haifar da toshe na'ura. An bayyana musamman a:

① Rashin isasshen tururi da babban abun ciki na danshi na iya haifar da abu cikin sauƙi don ɗaukar ruwa mai yawa. A lokaci guda, lokacin da matsa lamba ya yi ƙasa, yawan zafin jiki lokacin da kayan abu ya kasance mai sauƙi, kuma sitaci ba zai iya gelatinize da kyau ba, yana haifar da mummunan sakamako na granulation;

② Ruwan tururi ba shi da kwanciyar hankali, yana canzawa daga babba zuwa ƙasa, kuma ingancin kayan abu ba shi da tabbas, yana haifar da manyan sauye-sauye a halin yanzu na granulator, ƙishirwa mara kyau, da sauƙi mai sauƙi a yayin ayyukan samar da al'ada.

Don rage yawan tsayawar injin da ingancin tururi ya haifar, ma'aikatan masana'antar abinci suna buƙatar kula da abun ciki na danshi na kayan bayan tempering a kowane lokaci. Hanya mai sauƙi don tantancewa ita ce ɗaukar hannun hannu na kayan abu daga kwandishan kuma riƙe shi a cikin ball, sannan ku bar shi kawai ku watsar da shi.

4.Amfani da sabon zobe ya mutu

4.Amfani da sabon zobe ya mutu

Gabaɗaya magana, lokacin da aka fara amfani da sabon zobe na mutu, yana buƙatar ƙasa da kayan mai, tare da haɓakar da ya dace na kusan 30% na yashi emery, kuma ƙasa na kusan mintuna 20; Idan akwai abubuwa da yawa a cikin ɗakin granulation, kuma halin yanzu yana raguwa idan aka kwatanta da niƙa, yana da ingantacciyar barga, kuma haɓaka yana da ƙananan. A wannan lokacin, ana iya dakatar da injin kuma ana iya bincika yanayin granulation. A granulation ne uniform kuma ya kai fiye da 90%. A wannan gaba, yi amfani da kayan mai don danna ciki da maye gurbin kayan yashi don hana toshewar gaba.

Idan an toshe ƙirar zobe a lokacin aikin samarwa, yawancin masana'antun abinci suna amfani da na'urorin lantarki don fitar da kayan, wanda zai lalata santsin ramin ƙira kuma ya zama mai lahani ga ƙayatattun ƙwayoyin cuta.

Hanyar da ta fi dacewa ita ce a tafasa zoben zobe a cikin mai, wato a yi amfani da kwanon man karfe, a zuba man injin datti a ciki, sannan a nutsar da abin da aka toshe a cikinsa, sannan a yi zafi a rika tururi a kasa har sai an samu sautin tsagewa, sannan a fitar da shi. Bayan sanyaya, an kammala shigarwa, kuma an sake kunna granulator bisa ga ƙayyadaddun aiki. Za'a iya tsaftace kayan da ke toshe ƙirar zobe da sauri ba tare da lalata ɓacin rai ba.

Lokacin aikawa: Jul-19-2023